Director of Automated Packaging Solutions N.A. for Sparck Technologies, Sean Webb, recently sat down with Dave Blanchard, Senior Director of Content for Material Handling & Logistics, to discuss the benefits automated packaging can bring to your fulfillment operation on Material Handling & Logistics’ podcast, The Tool Belt.

With e-commerce here to stay, increased demands on your packaging and shipping process consume valuable time, money and labor resources. Add final-mile challenges and heightened delivery expectations, and these all put unique pressures on the nation’s fulfillment operations.

There is little doubt that the race to faster, more efficient package fulfillment and shipping has been accelerated, and by implementing automated packaging, companies can effectively overcome most of these challenges while gaining that competitive advantage and future-proofing their operation

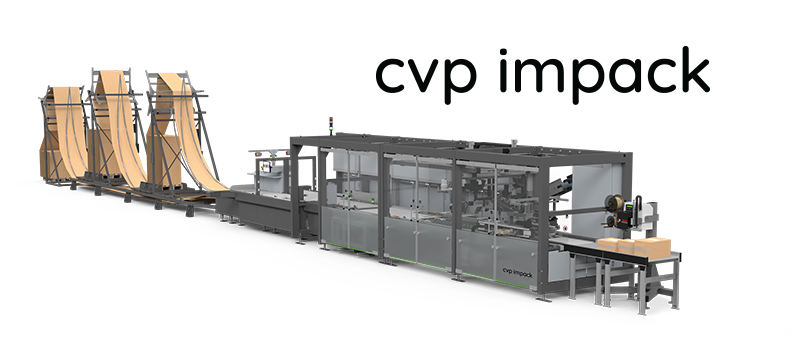

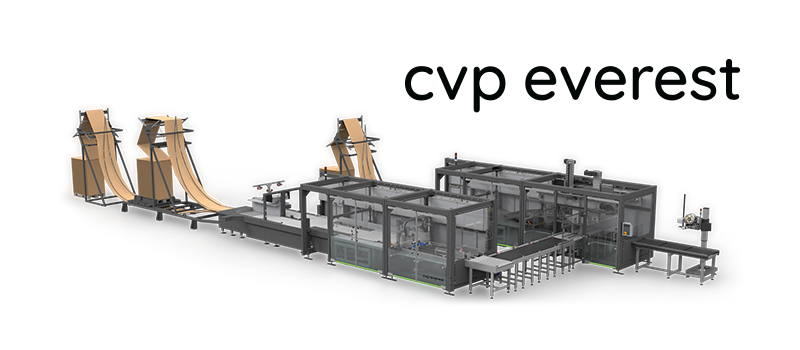

The CVP Automated Packaging Solution’s two models, CVP Impack and CVP Everest, optimize order fulfillment, decrease labor costs and reduce package volume for shippers across a variety of industries. The auto-boxing systems measure, construct, seal, weigh and label each custom single- or multi-item order in a fit-to-size box while eliminating or reducing the need for void fill. The CVP Impack packs up to 500 parcels per hour requiring only one or two operators while the CVP Everest auto-boxes up to 1,100 parcels per hour and uses two operators. These solutions offer a 50% reduction in shipping volume and 88% reduction in packing labor, providing some customers with a full return on investment in as little as 6 to 18 months depending on parcel volume.

Top 4 Podcast Takeaways

To read the transcript of Sparck Technologies and Material Handling & Logistics podcast, click here. The podcast is available on Apple Podcasts, Google Music, Spotify and Stitcher.

For more information on Material Handling & Logistics’ podcast, The Tool Box, you can find their website here.