CVP EVEREST

Reliable, regardless the peak.

Revolutionary Auto-Boxing Technology

Up to 1100 Boxes Per Hour

Fit-to-size auto-boxing technology measures, constructs, seals, weighs and labels each hard or soft single- or multi-item order in one consistent process. Increase packaging process efficiencies while saving on labor, shipping and material costs. See how the CVP Everest works to save you valuable time and money.

REDUCTION IN

PACKAGING LABOR

High throughput using the same amount of floor space as 10-20 manual packing stations, creating more work space for revenue driven activities.

REDUCTION IN

SHIPPING VOLUME

Package a diverse product mix of hard or soft single- or multi-item orders in the minimum-sized box required.

HIGH VELOCITY

PACKAGING

Later cut-off times due to the speed of packing, enabling same day delivery.

REDUCTION IN

MATERIAL COSTS

Reduce corrugate spend and minimize or eliminate void fill usage with a fit-to-size box.

Automation Efficiencies

Watch Everest In Action

Learn how the CVP can reduce labor, shipping and material costs while keeping you ahead of the competition and streamlining your packaging process.

Auto-Boxing Designed For You

DUAL INDUCT STATION

Dual Induct Station allow two operators to introduce single- or multi-item orders to maximize operational efficiency and throughput.

MONITORING & REPORTING

Our comprehensive suite of data products enables you to access your machine’s detailed and timely performance data, allowing you to manage and optimize your automated packaging operations.

PRINTING ON THE BOX

Personalized printing. Custom messages, logos and branding can be individually tailored for each and every package. High print quality at up to 360 dpi.

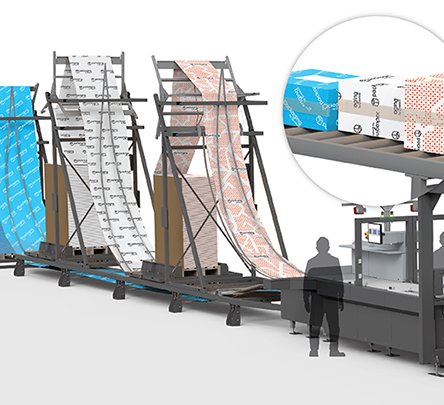

MULTI-CORRUGATE FEEDER

Multi-Corrugate Feeder automatically feeds the right corrugate width for the widest range of box sizes while minimizing corrugate waste. Increase uptime with one, two or three feeders of branded or unbranded corrugate.

Sustainability: 5 Steps to Improving the Value of Your Parcel Packaging Process

Priorities for shippers today are never-ending. As we continue to transition from shelf to doorstep with a growing emphasis on sustainable practices, businesses must investigate all parts of the order fulfillment design to reduce their carbon footprint while saving valuable money. Learn more about the current state of business driven sustainability and how automating your packaging process can boost your green efforts.

Ready to be a fearless auto-boxer?

We’re here for you, and we are wearing our thinking caps.

Get in touch with our team to start the conversation.