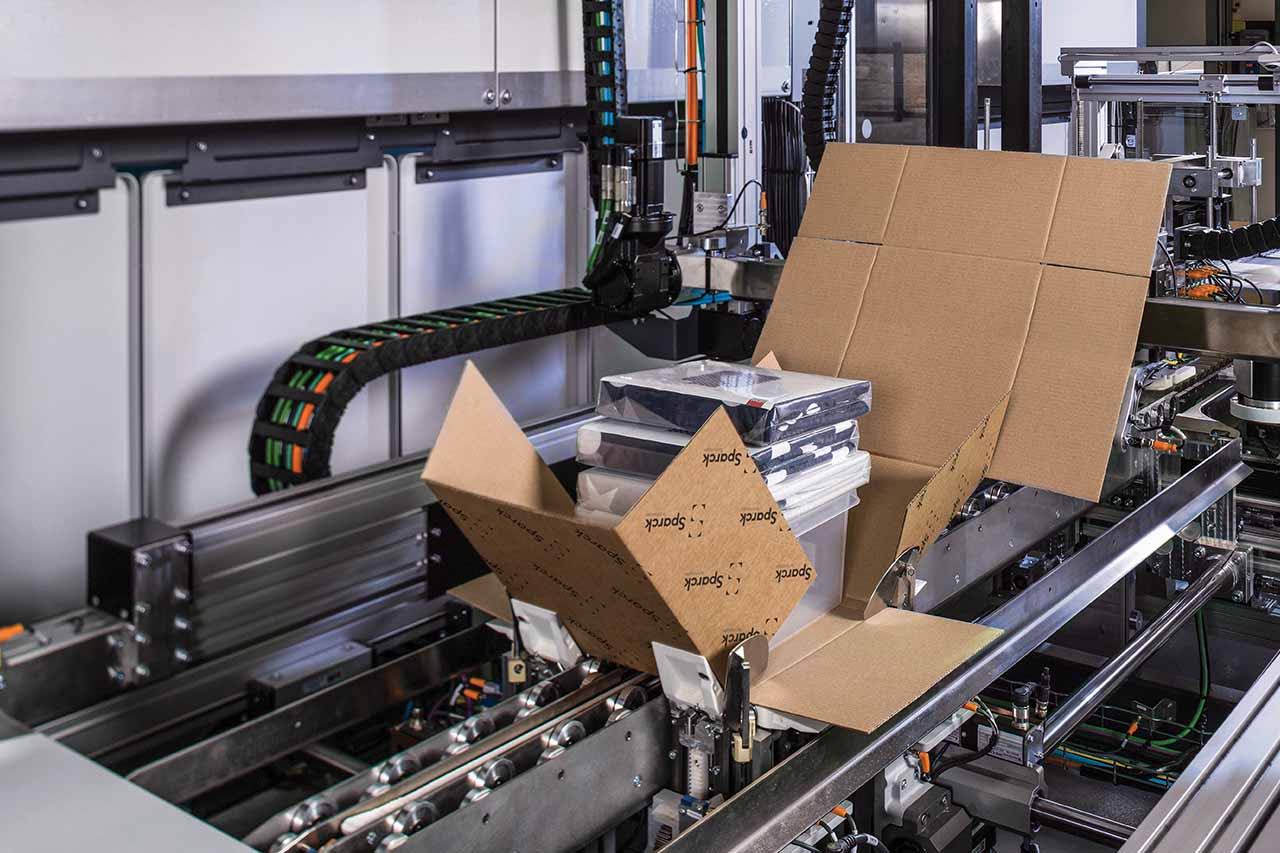

Say goodbye to labour intensive excess packaging

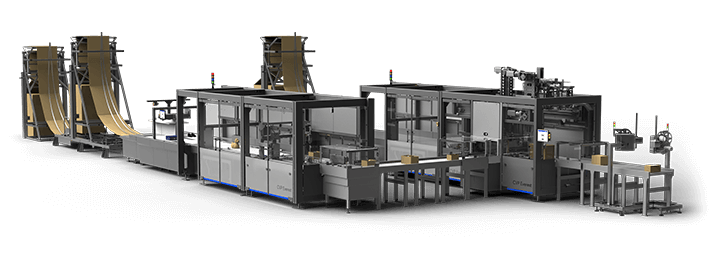

With the capability to tailor-make up to 1,100 packages per hour, for multiple or single item orders, Sparck’s packaging systems offer automated solutions for ecommerce operations challenged by increasing order volumes, labour shortages and growing demands for sustainable packaging solutions.

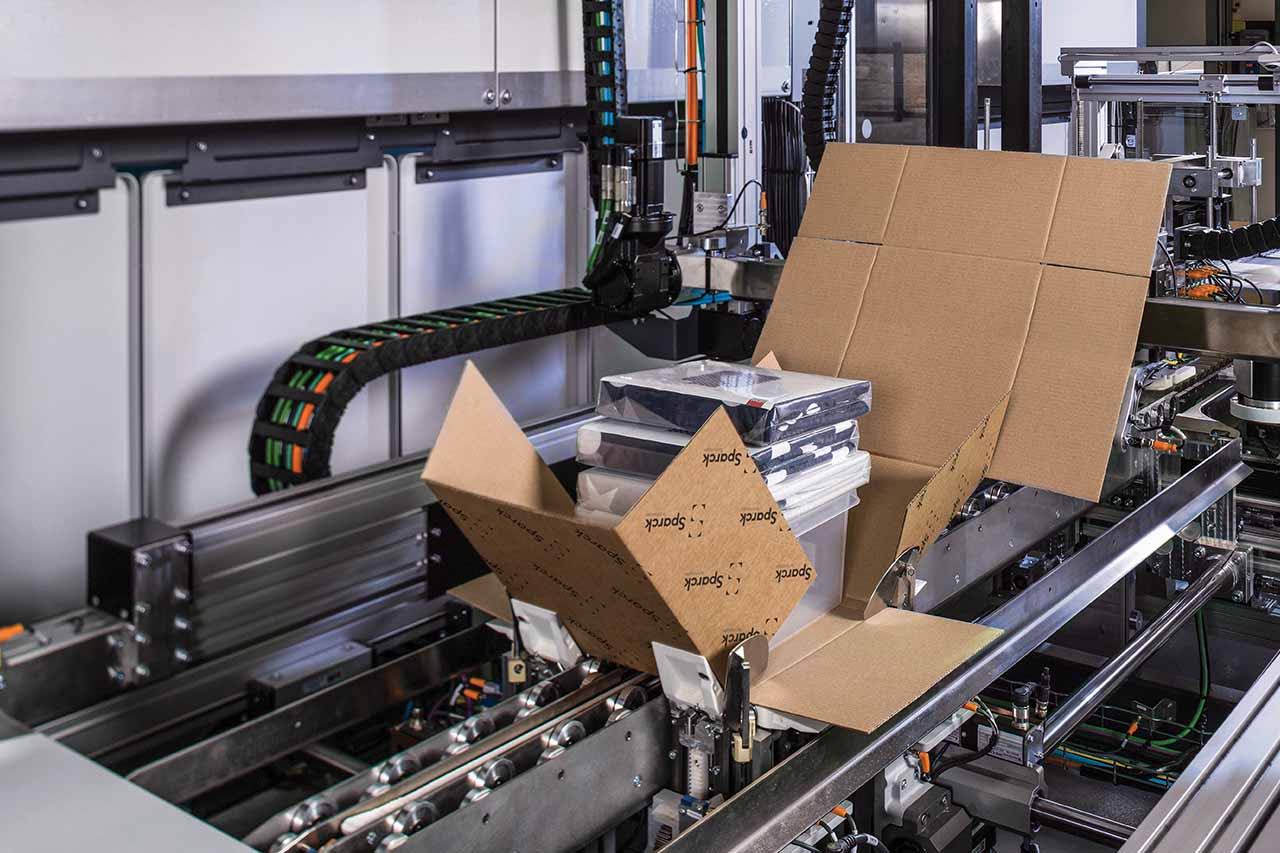

Using 3D scanning technology, these award winning automated packaging solutions will build, seal, and label a fit-to-size shipping box around each unique order in just a matter of seconds. From the smallest of garment items that can fit through a letterbox, right up to products the size of a vacuum cleaner – flexibility that offers over 40 million different box sizes.

Accelerate fulfilment and grow your business across a wide range of industries including e-commerce, fashion, toys, 3PL, manufacturing, wholesale, spare parts, pharmaceutical, health & beauty and many more.

Our packaging solutions

Sparck Technologies’ CVP Everest and Impack auto-boxers are able to pack single- and multi-item orders in one seamless flow. These supercharged solutions will keep up with your high volume fulfilment needs while supporting those ever changing peaks. By creating the smallest box necessary, you will improve the customer experience with sustainable packaging.

CVP Impack

Create a right sized box every 7 seconds

Up to 500 boxes per hour

CVP Everest

Or step it up to every 3 seconds

Up to 1,100 boxes per hour

Oversized boxes are the scourge of ecommerce fulfilment. The environmental case for ending the common practice of shipping retail goods to consumers in grossly oversized boxes is unassailable. The CVP Automated Packaging Solutions create a right sized boxed for every consignment, reducing package volumes by up to 50%, cutting cardboard usage by 30% and eliminating the need for void fill.

These inline solutions fully integrate with your warehouse management system to help you flexibly meet demands and future growth.

How does automated packaging work?

Place order on induct station

Place order on induct station

Single- or dual induct station where operators start the process by scanning each unique barcode to retrieve the correct shipping label.

Fit-to-size packaging

Fit-to-size packaging

Each unique order is 3D-scanned to determine the minimum box size required. Corrugate is custom cut to eliminate unnecessary volume and the need for void fill. Order is then auto-packed in a fit-to-size box.

Fit-to-size packaging

Fit-to-size packaging

Each unique order is 3D-scanned to determine the minimum box size required. Corrugate is custom cut to eliminate unnecessary volume and the need for void fill. Order is then auto-packed in a fit-to-size box.

Box is sealed, weighed and labeled

Box is sealed, weighed and labeled

Every box is securely sealed, weighed on the in-line scale, and automatically receives a carrier-compliant shipping label.

Benefits

LABOUR CHALLENGES

The CVP automated packaging solutions are in-line auto-boxers and can on average replace up to 20 manual packaging stations at a time, thus reducing labour costs while increasing packaging process efficiencies.

SHIPPING VOLUME

Why pay to ship air? Right sized packaging on average reduce box volume up to 50% by creating the smallest parcel needed at the lowest expense. This results in the lowest possible shipping costs and eliminates void fill usage.

SUSTAINABILITY

Automate your packaging to strengthen your green initiatives. Oversized boxes are the scourge of ecommerce fulfilment. By consistently making each box to the exact dimensions needed, shipping volumes can be reduced by up to 50% and cardboard usage can drop by 30%.

PEAK READY

Every year customer demands get higher and ecom companies are pushed to the edge. Alleviate peak season packaging challenges with realiable auto-boxing. Even when labour resources are scarce.

Case study

WebstaurantStore USA

As the largest ecommerce food service equipment and supplies dealer in the United States, WebstaurantStore’s mission is to offer busy foodservice professionals superior service, fast shipping, and the best selection and prices. Faced with continued growth and an extremely diverse order profile, WebstaurantStore turned to the CVP Automated Packaging Solution for efficient packaging.

As the largest ecommerce food service equipment and supplies dealer in the United States, WebstaurantStore’s mission is to offer busy foodservice professionals superior service, fast shipping, and the best selection and prices. Faced with continued growth and an extremely diverse order profile, WebstaurantStore turned to the CVP Automated Packaging Solution for efficient packaging.

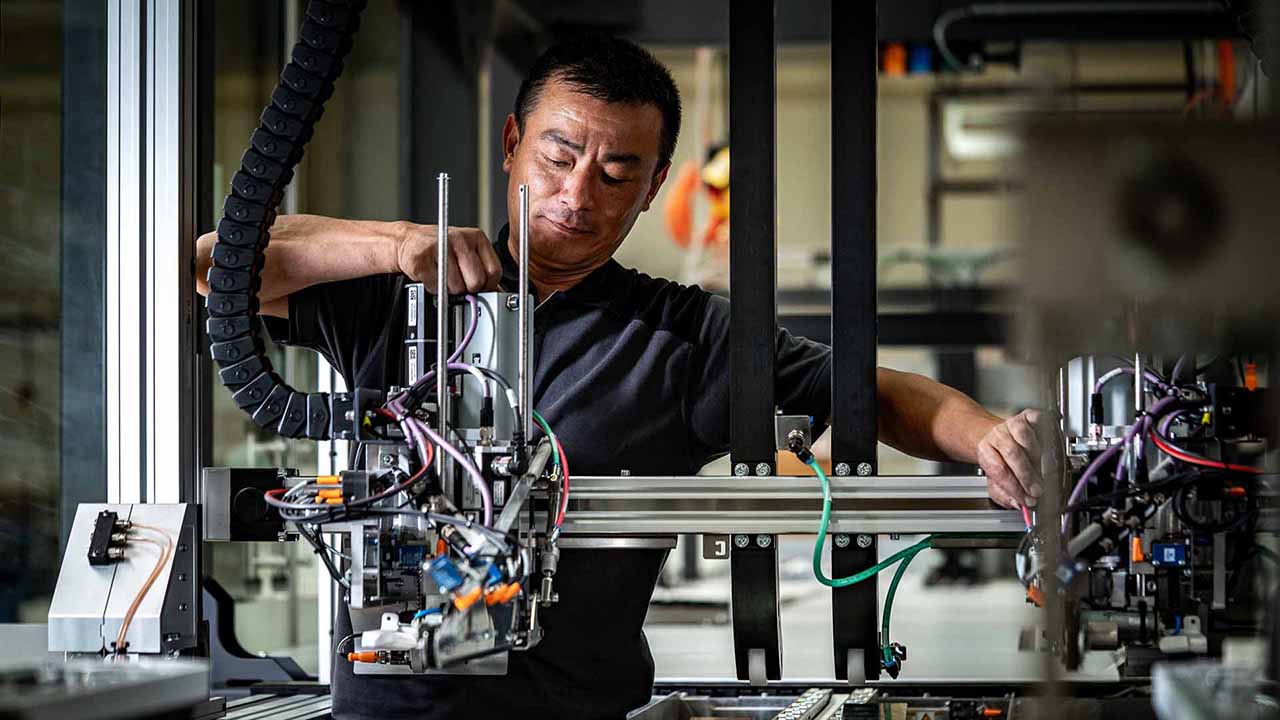

Reliable packaging automation

Get more value out of automated packaging

Sparck makes a personal commitment to deliver the best customer experience in the industry When you invest in automated packaging, you expect unmatched high performance. Our customers are pleased with the CVP uptime and our service options that can be customized to your needs, including remote support, daily reporting, on-site services, parts support, product training, and software maintenance.

The CVP Impack machines have delivered significant cost and environmental benefits too, with reduced material use and volume savings on transportation.

The uptime and performance is great, and the ROI has outperformed our projections. The CVP Impack has hit just about every metric we set for it.

Sparck trained our employees both operationally and technically, and together with our people, they constantly reviewed the operation during installation.

Thanks to the CVP, we can handle strong increases in demand without additional labour in the shipping area.

Sparck’s packaging systems are highly flexible, capable of producing tailor-made packages at speed, whilst being able to cater for single or multi-item orders with differing product profiles.

When I first saw the CVP machine in action, I was in awe honestly. The speed was insane. With two operators, we’ve allowed ourselves to become seven times more efficient than we would without the machine.

The amazing thing about the packaging solutions from Sparck Technologies is that they not only offer a sustainable packaging process, but also speed up the order processing.

It’s a fabulous piece of kit. The CVP packs products in the most economically, environmentally friendly and protective way – at high speeds.

Let’s talk about packaging

Contact us to get started and see how automated packaging can boost your business.

Create the perfect fit-to-size parcel with the lowest possible costs.

SEE (formerly Sealed Air) is exclusive distributor of Sparck’s automated packaging solutions in Australia, New Zealand, Japan and South Korea. For more information please visit www.sealedair.com or contact Regan Roberts.

New Zealand

SEE (Official Partner)

Mr. Regan Roberts

Powered by

Sparck Technologies

Meet the mid-sized and enterprise-level companies who are benefiting from the efficiency and flexibility of our automated packaging technologies.

Powered by

Sparck Technologies

Meet the mid-sized and enterprise-level companies who are benefiting from the efficiency and flexibility of our automated packaging technologies.