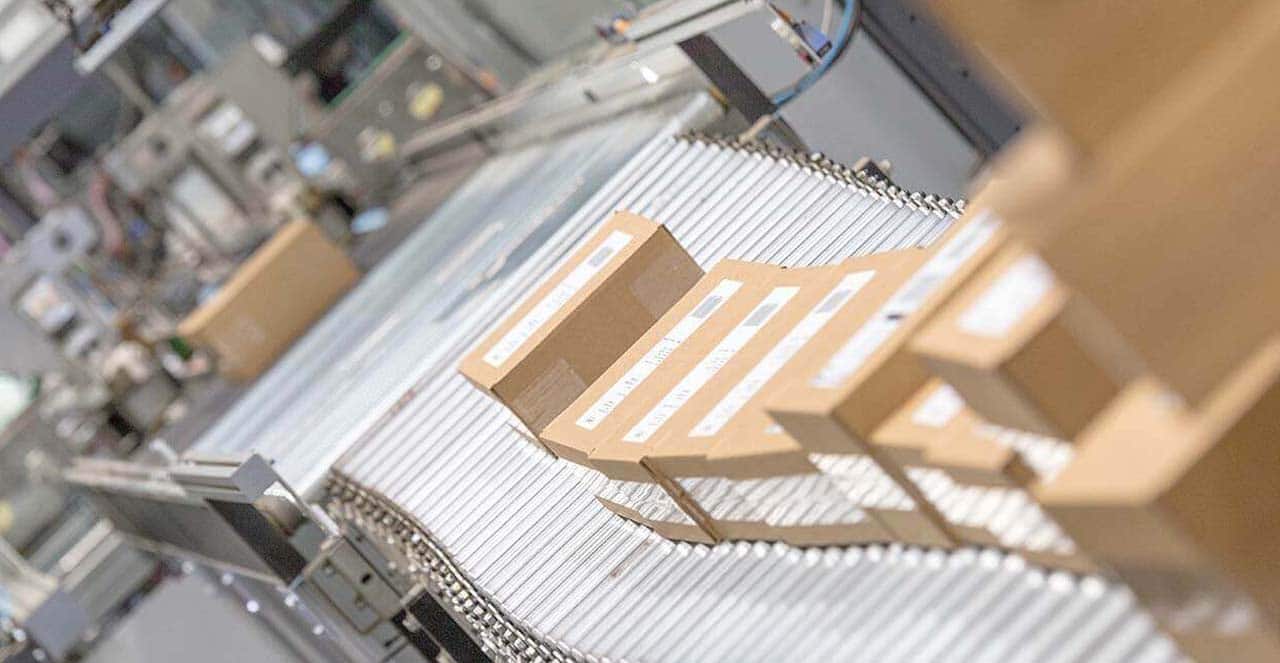

TOP PACKAGING CHALLENGES SOLVED

As increased buying power continues to create opportunity for a range of businesses, parcel packaging challenges can limit growth and compromise customer relationships.

What packaging challenges do you want to solve?

Labour

With parcel volume booming, warehouse labour shortages are at an all time high. Ensure all steps of the packaging process are optimized with automated fit-to-size packaging, even when labourers are hard to find.

Shipping volume

Why pay to ship air? Automated packaging will reduce shipping volume and material usage due to an optimized sized box.

Materials spend

The demand for and price of corrugate continues to rise. Reduce corrugate spend and eliminate larger than required boxes and void fill usage with fit-to-size auto-packing.

Speed

Time is money, and speed is the name of the packaging game. Automated packaging will increase throughput while using less.

Peak seasons

Every year customer demands get higher and companies are pushed to the edge. Alleviate peak season packaging challenges with automated packaging.

Read more

Sustainability

While fast delivery times continue to be a focal point, consumers also want to purchase from environmentally friendly companies. Automate your packaging to strengthen your green initiatives.

Read more

Reliability

Today’s shippers are looking for more reliable processes to get orders out without downtime. Drive trust-worthy process efficiencies with fit-to-size packaging.

Read more

Customer experience

Parcel packaging is an important component of the customer experience, yet many companies discount this final supply chain step. Auto-pack for great first impressions.

Find out how to pack smarter, faster and more efficiently with auto-packing

- High-speed inline auto-packer

- Fit-to-size box for each order

- Eliminates the need for void fill

- Volume reduction up to 50%

- Replaces up to 30 manual packaging stations