5 WAYS TO BOOST PACKAGING PERFORMANCE

Benefits of an automated packaging solution

- Increase capacity

- Build in sustainability

- Reduce shipping costs

- Increase operational efficiency

- Enhance the customer experience

Five key points to consider when adopting automation in the packaging area

The pandemic has been a catalyst for change, way beyond our expectations. Ecommerce has been propelled to new heights, with online order volumes swamping conventional fulfilment centres. Now, as a second wave sweeps the country, are businesses ready for the predicted mega-peaks of a Covid Christmas?

Leading into the Christmas period, most ecommerce operations take on additional staff to match demand, but a shortage of available labour, exacerbated by Brexit and a diminishing pool of migrant workers – coupled with the constraints imposed by social distancing requirements – has created a ‘perfect storm’ for ecommerce businesses.

Many retailers with a busy online channel will need to ask themselves the question: Is a conventional, heavily manual approach to preparing orders for dispatch still fit for purpose?

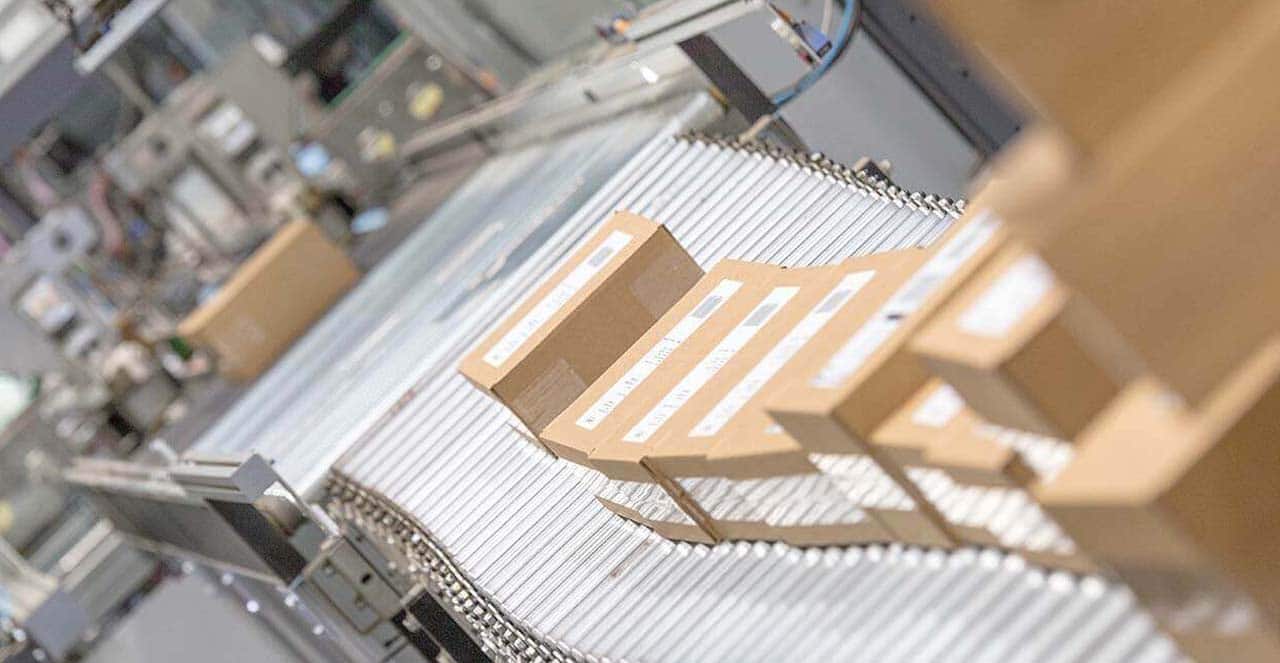

Fulfilling an ecommerce order has always been thought of as an inherently labour intensive activity, involving large teams of pickers and packers. But in the packing area advanced fit-to-size automated packaging technology is transforming operational performance, overcoming many of the obstacles presented by the Covid crisis and providing businesses with significant gains on sustainability, cost reduction, and customer experience.

Here are five key points to consider when adopting automation in the packaging area.

Boost your packaging performance with Sparck’s Automated Packaging Solutions, the CVP Everest and CVP Impack

Sparck Technologies offers two automated packaging solutions; the CVP Impack and the CVP Everest. Using this fit-to-size auto-boxing technology you can flexibly handle a wide variety of order sizes with one machine, creating a perfect-size box for each order at a rate of up to 1,100 packages per hour. Operating consistently and reliably at these speeds, the CVP Everest has the potential to replace between 20-30 packing desks, offering a rapid ROI.

The automated packaging process

SIZE

Each unique order is 3D-scanned to determine the minimum box size required. Single- or multi- item orders can be processed by one operator for maximum packaging productivity.

CONSTRUCT

Corrugate is custom cut to eliminate unnecessary volume and the need for void fill. The order is then auto-packed in a fit-to-size box, meaning there is no need for bubble wrap or other types of void fill. The CVP creates he smallest parcel needed at the lowest expense.

SEAL

The box is securely closed by tape (CVP Impack) or glue (CVP Everest). Because there is no unnecessary air inside the box the good are well protected. A strong and sturdy box will not only protect your valuable items, but also reduce returns. The box allows for easy opening, recycling or returns, improving the customer experience.

Powered by

Sparck Technologies

Companies worldwide benefit from a seamless packing process, saving costs while reducing box volume and corrugate consumption.

Let’s talk about packaging!

Create the perfect fit-to-size parcel with the lowest possible costs.