Nouvelles de Sparck

Dernières nouvelles

Podcast

Sean Webb

Directeur commercial, NA

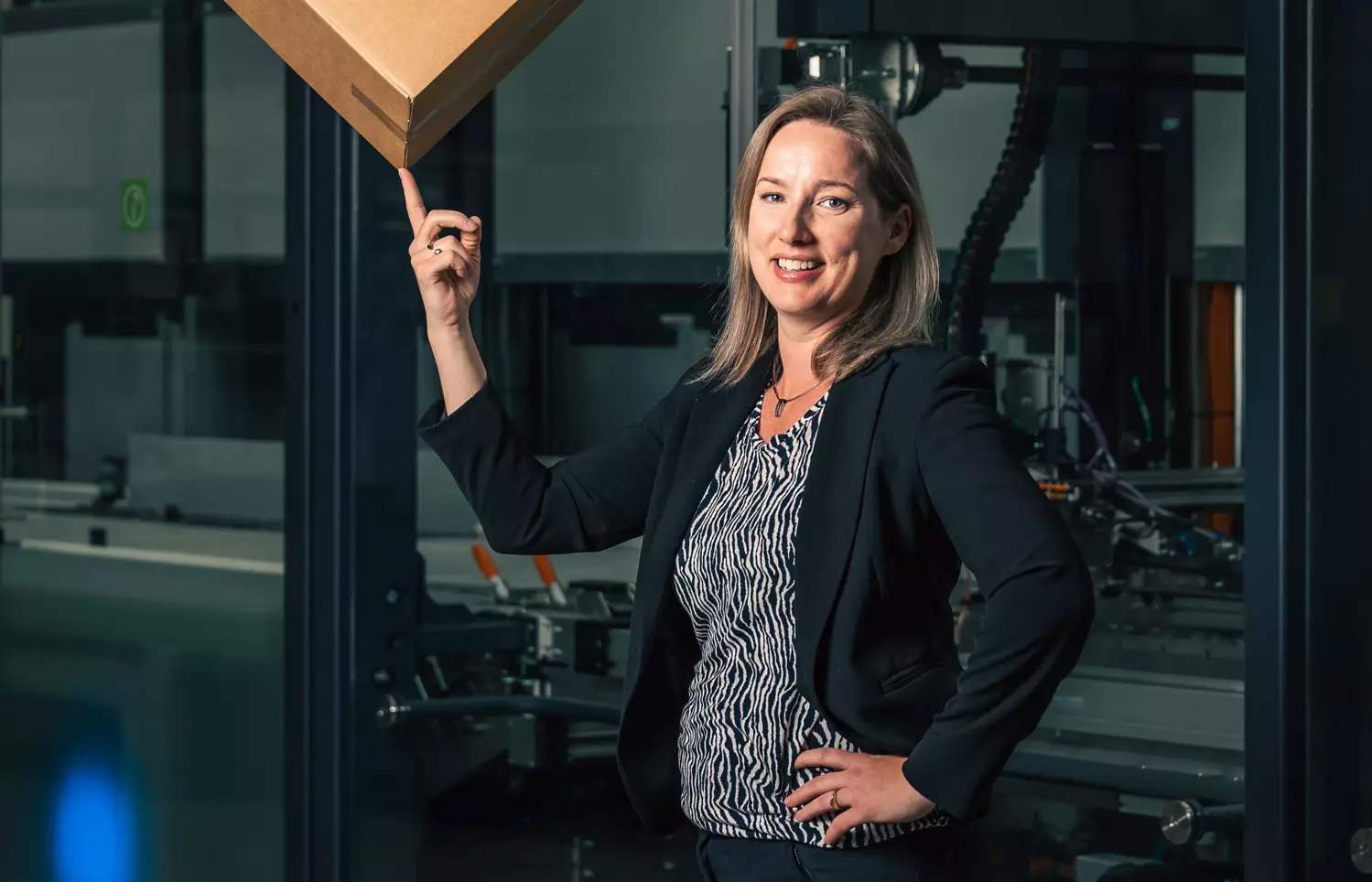

"Sparck joue un rôle essentiel dans le secteur de l'emballage avec pour mission de mettre en place une économie circulaire.

Téléchargements

Guides et conseils

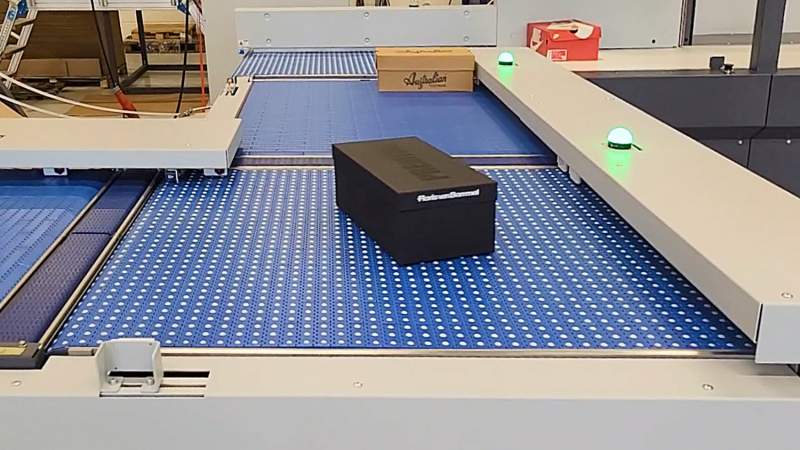

Chez Sparck, nous pensons que l'automatisation doit vous faciliter la vie. C'est pourquoi nous avons créé cette sélection de téléchargements pour vous aider à démarrer. Saute les obstacles et ouvre la voie à une vie plus légère et plus propre, remplie de haute technologie.