Enhancing customer loyalty through right-sized sustainable packaging

Sustainability has never been more top-of-mind for consumers than it is today. Now, they’re motivated to act on environmental sustainability and support companies that are investing in sustainable solutions.

What are Customers Looking For?

No longer a Unique Selling Point, but a necessity

Sustainability isn’t a ticket to heaven anymore for companies; rather, it’s a ticket to ride. In previous years, companies that invested and prioritized sustainability efforts were the first of their kind. In 2022, companies who have established environmentally-focused goals are perceived as normal or they’re expected. However, if a company has not already developed a sustainability plan, it negatively impacts a customer’s perception of them. With that said, there are two groups of consumers that companies are trying to reach when it comes to communication about their sustainability efforts: the people that expect you to incorporate eco-friendly practices in everything that you do, and those that are happily surprised when they find out a company is implementing a new sustainable practice.

A sustainable packaging strategy is the first step to creating loyal customers

As a result of a growing emphasis on sustainable practices, businesses must look at all parts of order fulfilment to reduce their carbon footprint. One developing focus for companies has been on eco-friendly packaging. According to a Statista report, eco-friendly packaging is important to one in three consumers in de UK. These findings present companies with a great opportunity to identify their consumers’ sustainability preferences and act on what is important to them. For example, more than half of UK consumers are concerned about a wide range of environmental issues pertaining to packaging, not just one single factor, such as plastic waste. Recognizing these shared values, allows companies to genuinely connect with their customers and create positive, lasting relationships.

Sustainable packaging is the first step to enhancing customer loyalty. While that business strategy can’t act alone, its significance cannot be ignored.

A sustainable brand is evident in its packaging

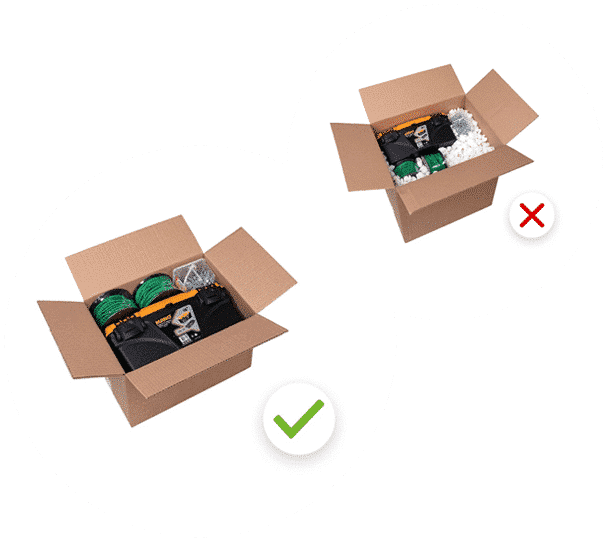

Packaging is the first thing that consumers look at when an item arrives at their doorstep and is the first criteria by which the item itself is judged. As the most outward testament to a brand and its commitment to sustainability, packaging should not entail an oversized cardboard box full of void fill for a small item ordered. Instead, when their package arrives, consumers should receive a sustainable, fit-to-size box to make a worthwhile impression when they open it.

Unboxing videos give brands a global presence, make sure it is a good one!

Unboxing is a rapidly growing video trend that points to the importance of this step in the process. The New York Times reports that there are 74 million unboxing videos on various social media channels that showcase the good, the bad and the ugly of online order packaging. Some videos feature the excitement of a consumer receiving their order, while others take a more critical point of view with them speaking out against online retailers. These negative videos show the amount of added void fill used for the order and the use of non-recyclable packaging. With the company name or branding visible to the whole world, they must ensure that every package leaving their warehouse is made just right; otherwise, one bad experience can dissuade customers from returning the next time they shop online.

Not only is there a growing pressure on companies to intentionally focus on sustainability, but they’re also plagued with ongoing labour shortages and increased shipping costs. To alleviate any customer woes, many retailers are turning to automated packaging systems for every order.

Top 5 Customer Demands

There is a solution in right-sized automated packaging

Using 3D scanning technology, Sparck Technologies’ automated packaging systems size, construct, weigh and label each individual order – regardless of whether it is made up of individual or multiple items in just a matter of seconds. The CVP Impack Automated Packaging Solution packs up to 500 orders per hour. With a cycle time as short as three seconds, the CVP Everest can do the work of up to 20 packing stations – constructing up to 1,100 fit-to-size boxes per hour. Due to fit-to-size packaging, it also offers up to 50% reduction in shipping volume, resulting in fewer truckloads and reducing CO2 emissions.

These proven auto-boxing technologies generate highly effective packaging and optimize all steps of parcel fulfilment while saving on labour, shipping and material costs and are easy to reuse or recycle.

Efficient, eco-friendly order fulfilment

With automated packaging solutions, right-sized sustainable packaging is no longer a pain point. These solutions allow shippers to create better warehouse efficiencies while keeping up with customer demand for sustainable packaging. In addition to sustainability, customers will enjoy these fit-to-size parcels as this type of packaging has been found to cause less damage to orders while in transit.

By creating the smallest parcel necessary, businesses can lessen their environmental impact and lower shipping material costs for a more environmentally friendly parcel. With a more efficient, eco-friendly order fulfilment made possible, it will ultimately increase customer loyalty and satisfaction.

Reduce costs and retain happy customers with automated packaging.

Is your business feeling the pressure to respond to customer demands while streamlining operating and material costs? If so, download our customer experience white paper and learn how switching your packing process to a fully automated packaging solution is the answer you’ve been waiting for.

Say goodbye to labour intensive, oversized packaging!

Create a right sized box every 7 seconds

CVP Impack

Increased efficiencies

Up to 500 boxes per hour

Or step it up to every 3 seconds

CVP Everest

High-speed packaging

Up to 1,100 boxes per hour

Discover how these companies improved their Customer Experience

The performance of the CVP Impack has exceeded our expectations. It has hit just about every metric we set for it. We’re very pleased with how its performing.

The CVP Impack is designed to be extremely user friendly and handle a broad range of our products in one seamless flow.

In terms of shipping volumes, our calculations indicate that the two CVP Impack machines will offer a reduction of 92 truck loads a year, due to the space savings of fit-to-size packaging.

In partnership with Sparck , we are constantly reviewing the capabilitgies of the CVP Impack which has led to a great success. Sparck is always prepared to review and improve itself on the basis of someone else’s insights.