Sustainability

Sparck is committed to leveraging resources responsibly, aiming to benefit both our customers, community and the environment. Together, we are shaping a sustainable future through fit-to-size automated packaging.

One with

water

Our headquarters is based in The Netherlands. A home that has historically been a difficult place to live, but an even harder place to leave, as it’s so easy to love. With rising sea levels and our relationship with the land - or ‘waterscape’ around us, we’re committed to taking meaningful steps to reduce our footprint.

Curious about your sustainability rate?

Find out how much your business can improve it’s sustainability rate by integrating automated fit-to-size packaging.

How many boxes

do you ship yearly?

On a mission

to eliminate emissions

Current and upcoming EU legislation regarding sustainability in the supply chain focuses on ensuring businesses uphold environmental and social responsibility throughout their operations.

Automated fit-to-size packaging reduces material usage, minimizes corrugate waste, and eliminates unnecessary empty box space, leading to a decrease in your carbon footprint.

Reduce your carbon

footprint

Our automated fit-to-size packaging solutions minimize material usage by creating boxes tailored to each order, eliminating the need for excess dunnage and reducing corrugate waste. This results in an average 32% reduction in freight costs, as more parcels fit on a single truck, decreasing the number of truckloads on the road.

From ambition to action

Inspire

Innovate

Commitment

-

Commitment to sustainability

Sparck is dedicated to leading the way in sustainable packaging, aiming to inspire both current and prospective customers through innovative automated solutions. Our CVP Impack and CVP Everest packaging solutions use smart technology to package orders more sustainably. Right-size automated packaging effectively reduce corrugate usage and eliminate the need for void fill, lowering overall cardboard consumption.

By making fit-to-size boxes, you can save up to 50% in box volume, allowing more parcels to be shipped simultaneously and reducing the number of freight trucks on the road. This reduces CO2 emissions and your environmental impact.

-

Innovations in green packaging

Our vision is to pioneer automated packaging solutions while leaving a positive global impact. Sparck’s fit-to-size automated packaging solutions are engineered to minimize the environmental impact of shipping packaging across its lifecycle, from production and use to disposal, while ensuring optimal product protection and delivery to consumers. Automated packaging for change means eliminating the need for excess packaging and void fill materials.

-

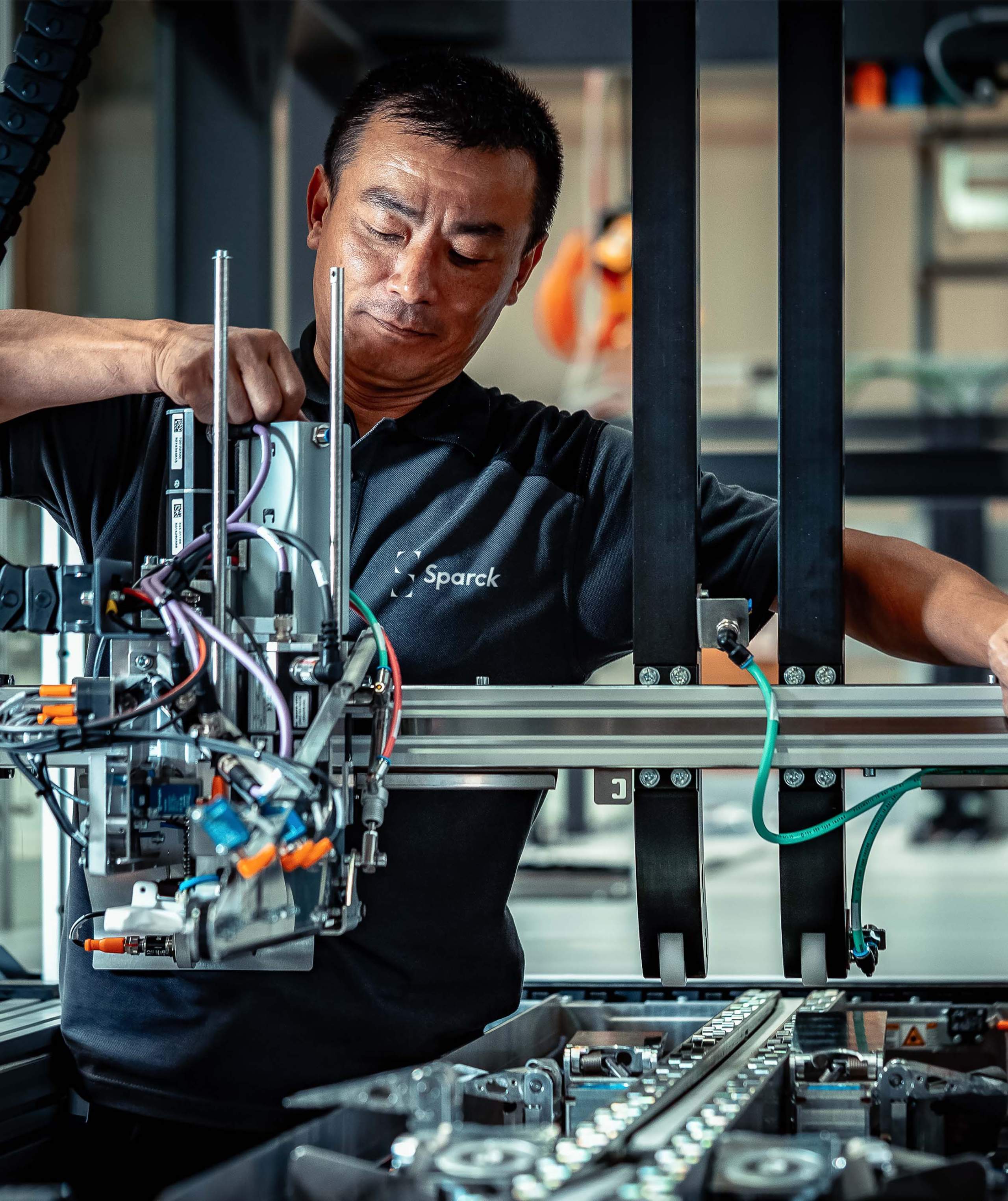

Efficient resource management

Efficiency is at the heart of all Sparck Technologies operations. We optimize resource usage by minimizing labor, consumption and waste generation. Our smart technology solutions are prime examples of how we contribute to resource efficiency. These products not only serve our primary purpose by also ensure resources are used judiciously.

Efficient – less labor resources and less usage of corrugate

Fit-to-size – cut and creased to fit perfectly around the product(s)

Sustainable packaging – no plastics or void fill

Save money – save costs & improve throughput

-

Commitment to sustainability

Sparck is dedicated to leading the way in sustainable packaging, aiming to inspire both current and prospective customers through innovative automated solutions. Our CVP Impack and CVP Everest packaging solutions use smart technology to package orders more sustainably. Right-size automated packaging effectively reduce corrugate usage and eliminate the need for void fill, lowering overall cardboard consumption.

By making fit-to-size boxes, you can save up to 50% in box volume, allowing more parcels to be shipped simultaneously and reducing the number of freight trucks on the road. This reduces CO2 emissions and your environmental impact.

-

Innovations in green packaging

Our vision is to pioneer automated packaging solutions while leaving a positive global impact. Sparck’s fit-to-size automated packaging solutions are engineered to minimize the environmental impact of shipping packaging across its lifecycle, from production and use to disposal, while ensuring optimal product protection and delivery to consumers. Automated packaging for change means eliminating the need for excess packaging and void fill materials.

-

Efficient resource management

Efficiency is at the heart of all Sparck Technologies operations. We optimize resource usage by minimizing labor, consumption and waste generation. Our smart technology solutions are prime examples of how we contribute to resource efficiency. These products not only serve our primary purpose by also ensure resources are used judiciously.

Efficient – less labor resources and less usage of corrugate

Fit-to-size – cut and creased to fit perfectly around the product(s)

Sustainable packaging – no plastics or void fill

Save money – save costs & improve throughput

-

Eliminate shipping air

50% reduction in shipping box volume while packaging a diverse product mix of hard or soft single or multi-item orders in the minimum-sized box.

-

Decrease material consumption

Our solutions enable you to save up to 30% on cardboard use because less of it is needed for packing your orders. Our solutions are fed by endless cardboard, which comes in a range of thicknesses. B-flute, C-flute or B/C flute are available, making sturdy and custom packaging available for every need.

This results in less cardboard consumption and purchasing, which in turn means less empty space in each box shipped and lower carbon emissions.

-

Fewer trucks, less emissions

Our CVP Impack and CVP Everest packaging solutions use smart technology to package orders sustainably. By making fit-to-size boxes, you can save up to 50% on volume. This results in fewer freight trucks because more parcels can be shipped at the same time, reducing the CO2 emissions and the environmental impact.

-

Recyclable corrugate

Our cardboard is fully recyclable and biodegradable, helping create a circular business operation. The solution can also be fed with recycled corrugate, supporting the sustainability cycle.

You can also opt to seal boxes with paper tape instead of plastic tape. This not only enhances the sustainability of packaging but also makes it easier to recycle without the added complication of having to deal with non-recyclable materials containing chemicals.

-

Positive unboxing experience

A positive customer unboxing experience that showcases your commitment to sustainability with an easy-to-recycle, fit-to-size eco-friendly box.

-

Eliminate shipping air

50% reduction in shipping box volume while packaging a diverse product mix of hard or soft single or multi-item orders in the minimum-sized box.

-

Decrease material consumption

Our solutions enable you to save up to 30% on cardboard use because less of it is needed for packing your orders. Our solutions are fed by endless cardboard, which comes in a range of thicknesses. B-flute, C-flute or B/C flute are available, making sturdy and custom packaging available for every need.

This results in less cardboard consumption and purchasing, which in turn means less empty space in each box shipped and lower carbon emissions.

-

Fewer trucks, less emissions

Our CVP Impack and CVP Everest packaging solutions use smart technology to package orders sustainably. By making fit-to-size boxes, you can save up to 50% on volume. This results in fewer freight trucks because more parcels can be shipped at the same time, reducing the CO2 emissions and the environmental impact.

-

Recyclable corrugate

Our cardboard is fully recyclable and biodegradable, helping create a circular business operation. The solution can also be fed with recycled corrugate, supporting the sustainability cycle.

You can also opt to seal boxes with paper tape instead of plastic tape. This not only enhances the sustainability of packaging but also makes it easier to recycle without the added complication of having to deal with non-recyclable materials containing chemicals.

-

Positive unboxing experience

A positive customer unboxing experience that showcases your commitment to sustainability with an easy-to-recycle, fit-to-size eco-friendly box.