Innovation through automation

for the next generation

Sparck Technologies is a global tech company specialized in automated fit-to-size packaging. From the first machine built in 1924 to today’s cutting-edge solutions, Sparck’s fascination with the power of automation has never wavered. With Sparck’s automated fit-to-size packaging solutions, businesses worldwide cast off their dependence on manual labor, electrify efficiency, cut transportation costs, and curb their carbon footprint.

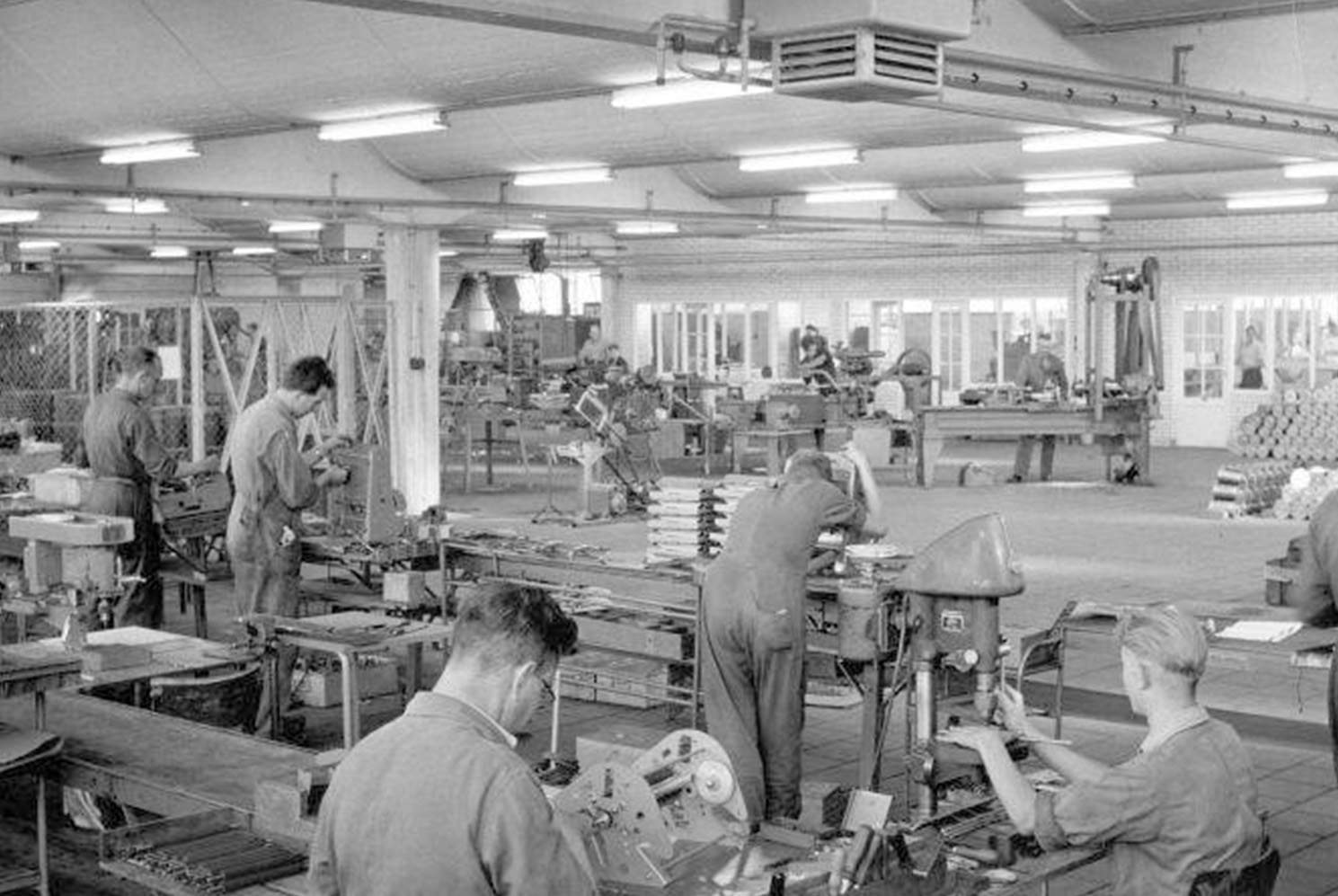

100 years of

automation

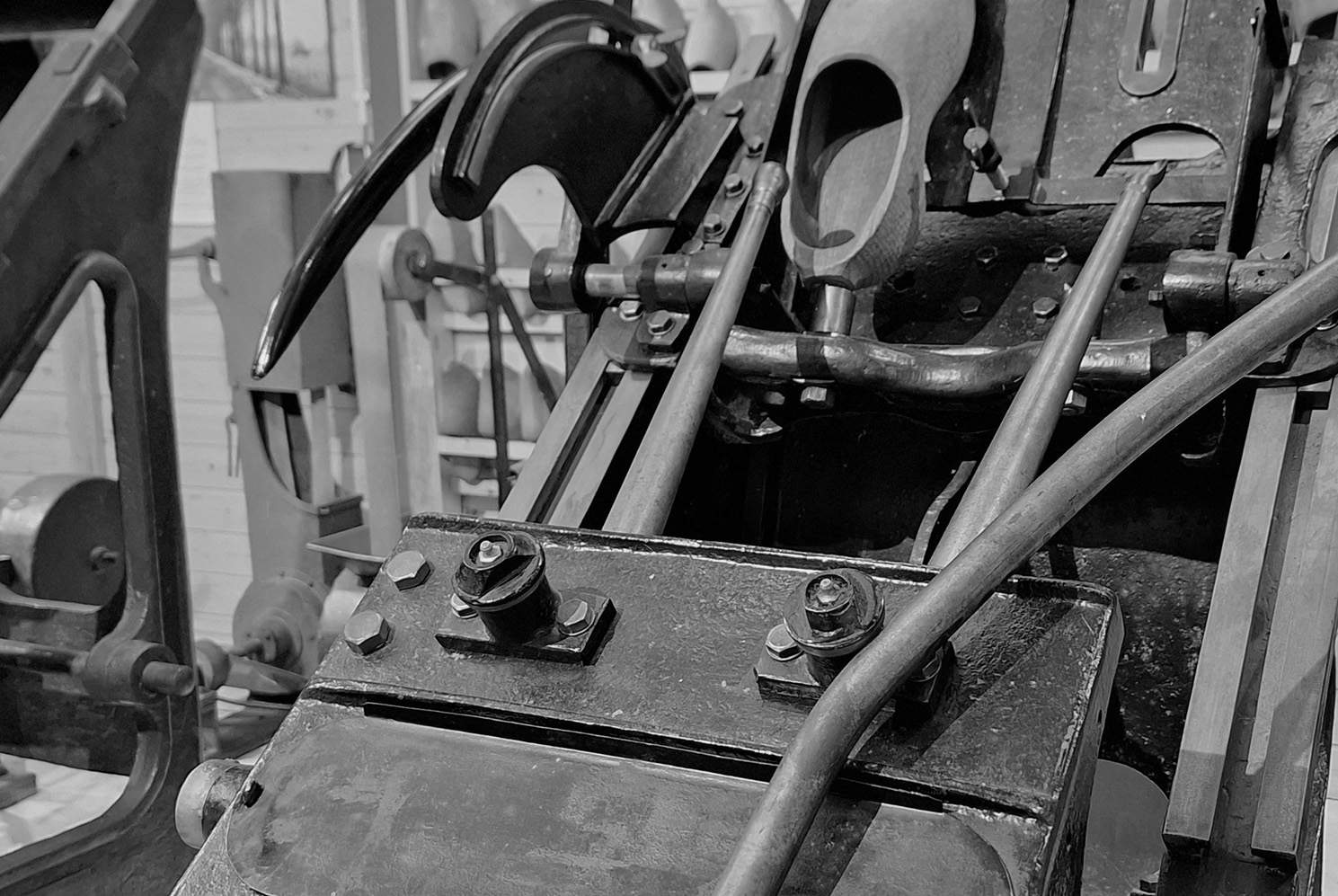

Founded in 1924 as HaDeWe in the Netherlands, our company has a rich history of innovation through automation. In our modest history, we succeeded to kickstart four technological revolutions. From automating Dutch wooden shoe production to introducing groundbreaking stencil and envelope stuffing machines, our journey has been marked by major technological advancements.

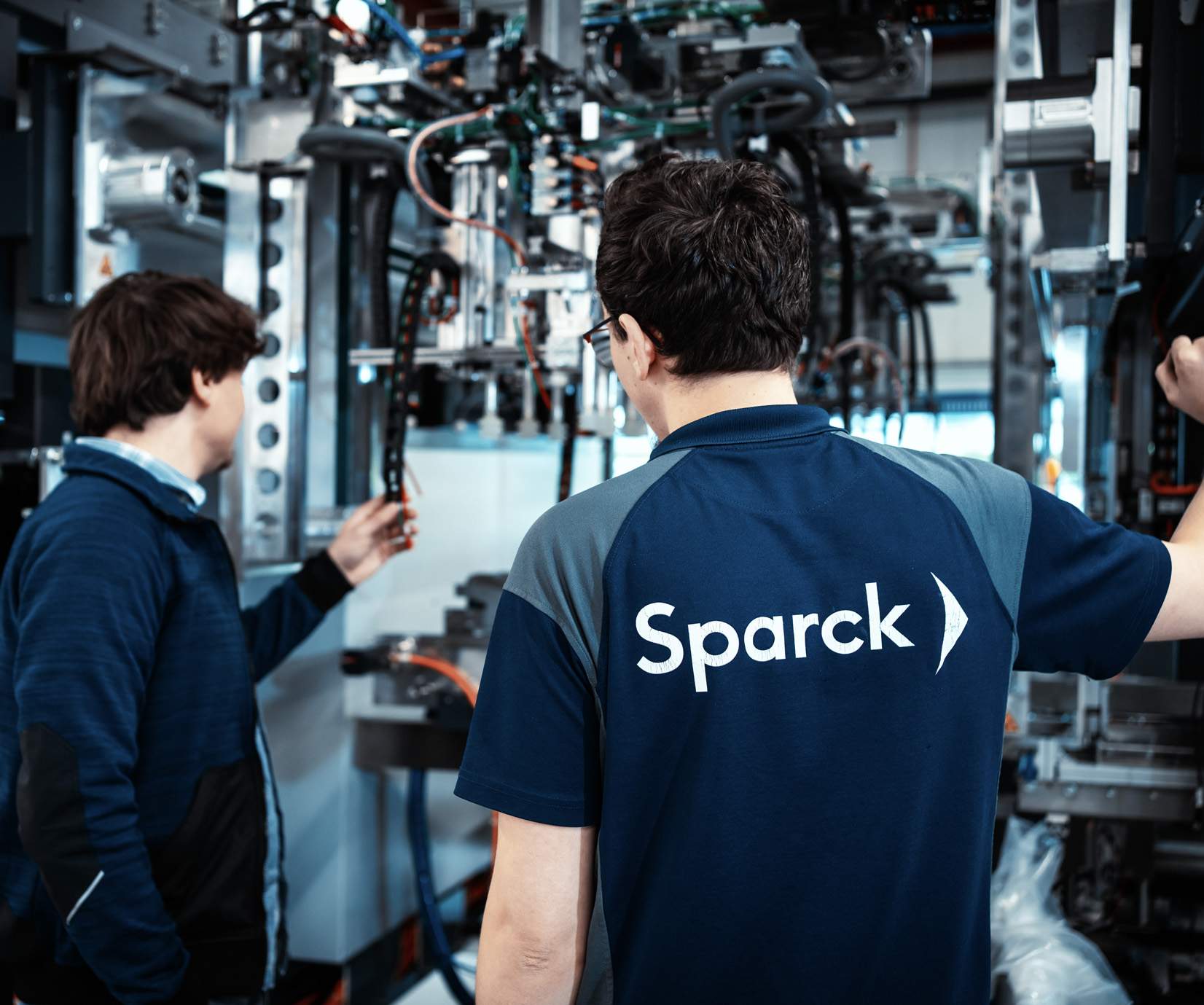

Engineers

at heart

In 2013, we embarked on a new path, driven by the demand for more efficient and sustainable automated packaging solutions. Our brilliant team of engineers blazed a trail of innovation with a revolutionary technology: smart automated fit-to-size packaging systems designed to reduce costs and minimize waste. This led to the development of our first fit-to-size automated packaging solution, the CVP Impack. Six years later, we unveiled the CVP Everest, capable of creating up to 1,100 boxes per hour. Since 2013, we have continued to evolve, launching multiple machine version and numerous new features.

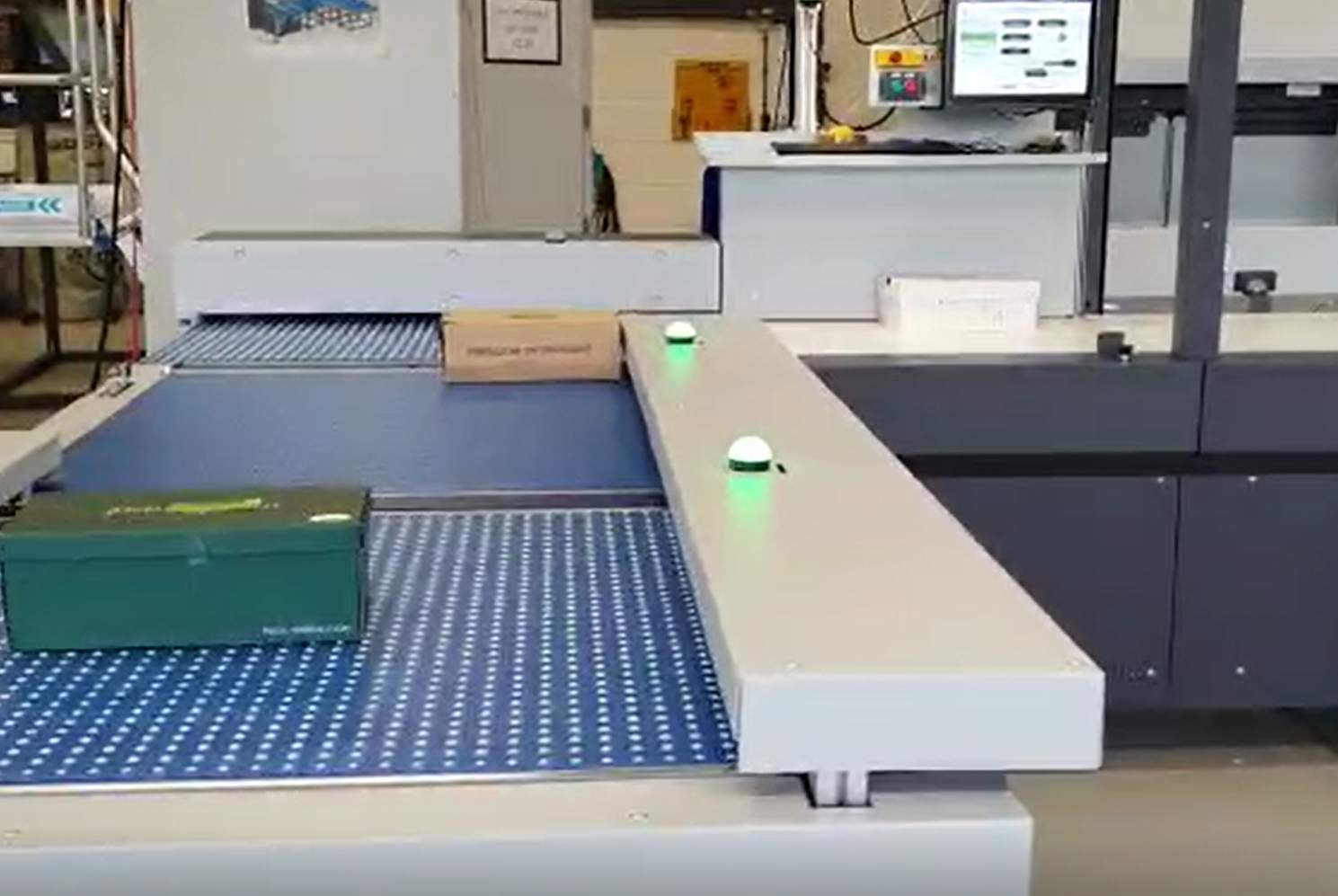

Our flagship

invention

First, a single- or multi-item order is placed on the induct station. The operator pushes the button and the order is advanced to a 3D scanner that measures the products to be packaged. The box is created around the order, sealed, weighed and labeled.

Built with pride,

made by humans

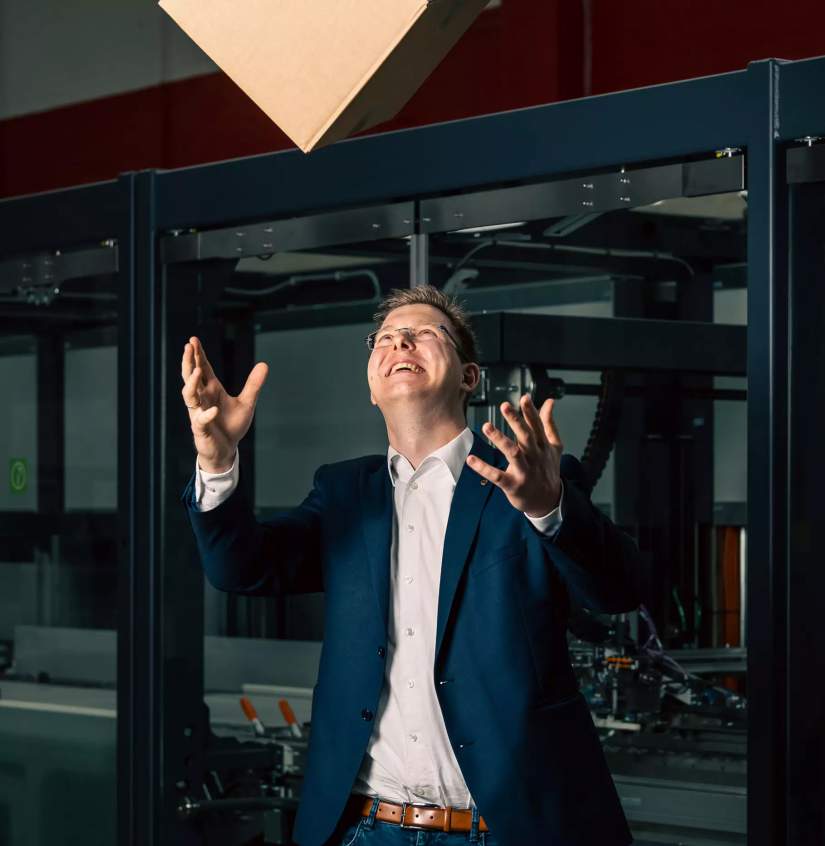

"At Sparck, we’re not only providers of fit-to-size automated packaging solutions; we’re enthusiastic engineers of innovations committed to adding a spark through performance.

With a century of automation expertise, our award-winning solutions enable businesses worldwide to streamline their packaging processes, electrify efficiency, and save valuable money. As we push boundaries to drive change and set new standards in automated packaging, sustainability, performance and efficiency are at the forefront of everything we do.

Our automated packaging solutions set the benchmark for performance, usability and efficiency. However, we go beyond the box…and our solutions; we’re committed partners consistently pushing boundaries.

We understand the unique industry complexities and evolving business needs. With unwavering dedication, reliable service and proven solutions, we stand as the ultimate partner, combining trust with leading technology."

Kees Oosting - CEO

-

Diverse perspectives drive innovation

At Sparck Technologies, we strive to prioritize diversity and inclusion of our workplace culture. We believe that a variety of perspectives and backgrounds leads to better innovation and solutions in our automated packaging technology. We are committed to providing an environment where all employees feel respected, valued, and empowered to contribute to their fullest potential.

-

Our commitment to sustainable packaging

At Sparck Technologies, we prioritize open communication and clarity in all aspects of our business, ensuring that our team members, customers, and stakeholders are informed and engaged. By fostering a transparent environment, we build trust and accountability, enabling us to collaboratively navigate challenges and capitalize on opportunities in automated packaging technology. Our commitment to transparency extends to our processes, decisions, and interactions, reflecting our dedication to integrity and excellence in all that we do at Sparck Technologies.

-

Trust through accountability

Sparck is dedicated to leading the way in sustainable packaging, aiming to inspire both current and prospective customers through innovative automated solutions. Our CVP Impack and CVP Everest packaging solutions use smart technology to package orders more sustainably. Right-size automated packaging effectively reduce corrugate usage and eliminate the need for void fill, lowering overall cardboard consumption.

By making fit-to-size boxes, you can save up to 50% in box volume, allowing more parcels to be shipped simultaneously and reducing the number of freight trucks on the road. This reduces CO2 emissions and your environmental impact.

-

Diversity & inclusion

Diverse perspectives drive innovation

At Sparck Technologies, we strive to prioritize diversity and inclusion of our workplace culture. We believe that a variety of perspectives and backgrounds leads to better innovation and solutions in our automated packaging technology. We are committed to providing an environment where all employees feel respected, valued, and empowered to contribute to their fullest potential.

-

Transparency

Our commitment to sustainable packaging

At Sparck Technologies, we prioritize open communication and clarity in all aspects of our business, ensuring that our team members, customers, and stakeholders are informed and engaged. By fostering a transparent environment, we build trust and accountability, enabling us to collaboratively navigate challenges and capitalize on opportunities in automated packaging technology. Our commitment to transparency extends to our processes, decisions, and interactions, reflecting our dedication to integrity and excellence in all that we do at Sparck Technologies.

-

Sustainability

Trust through accountability

Sparck is dedicated to leading the way in sustainable packaging, aiming to inspire both current and prospective customers through innovative automated solutions. Our CVP Impack and CVP Everest packaging solutions use smart technology to package orders more sustainably. Right-size automated packaging effectively reduce corrugate usage and eliminate the need for void fill, lowering overall cardboard consumption.

By making fit-to-size boxes, you can save up to 50% in box volume, allowing more parcels to be shipped simultaneously and reducing the number of freight trucks on the road. This reduces CO2 emissions and your environmental impact.

From Friesland,

with love

We are a global company, but our headquarters are based in Friesland, The Netherlands. A home that has historically been a notoriously difficult place to live, but an even harder place to leave, as it’s so easy to love. With rising sea levels and our relationship with the land- or ‘waterscape’ around us, we’re committed to taking meaningful steps to reduce our footprint.

About

our green dreams...

2024

Sparck Technologies celebrates its 100th anniversary

2024

250 million+ fit-to-size boxes produced globally

2024

20+ global industry awards won since 2015

2023

Sparck purchases E.pack Sp. z.o.o. in Poland

2023

Auto-infeed capability introduced

2022

Sparck Academy Innovation and Technology Center opens in Atlanta, GA US

2022

The introduction of slim-fit mailbox compliant box sizes

2021

Dutch investment firm, Standard Investment, acquires Packaging by Quadient and Sparck Technologies is born

2020

Advanced performance monitoring is implemented

2019

Launch of the CVP Everest

2018

Installs across 14 different countries

2017

CVP-500 version 5 introduced

2016

Installation of the first CVP Impack in the US

2015

Upgrade of machine to improve box size capabilities

2014

First commercial install of the CVP-500

2013

We embark on our new path to smart automated fit-to-size packaging, leading to the creation of the first prototype, the CVP-500

1990

We are sold to the French multi-national company Neopost

1983

Grand opening of our Drachten, The Netherlands production facility

1968

Introduction of our envelope stuffing machine

1936

Introduction of our first stencil machine

1924

HaDeWe is founded by Heert de Wit, the inventor of duplicators for wooden shoes