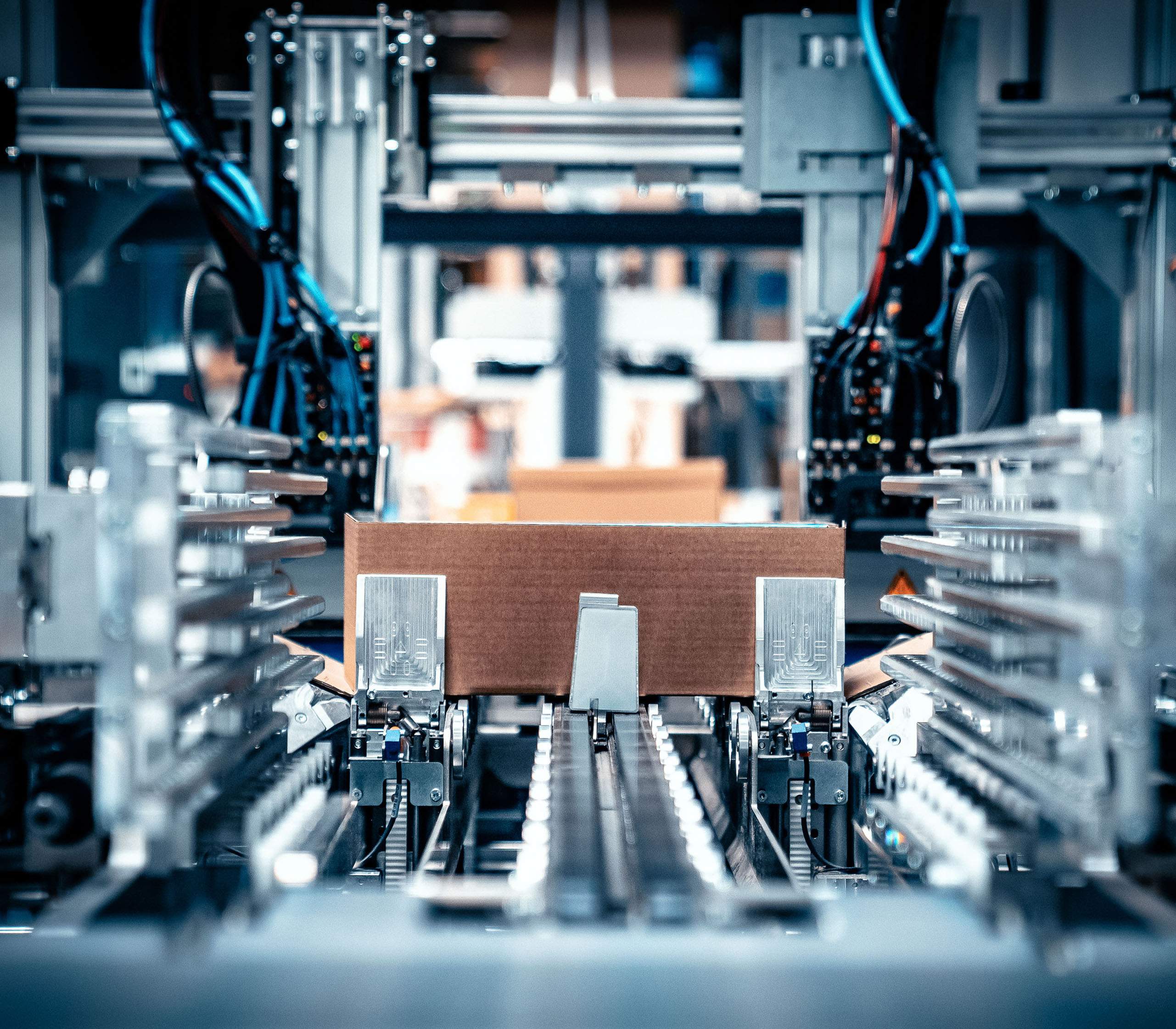

The spark of automated

packaging

Goodbye manual packing, hello automated

fit-to-size packaging. Electrify efficiency with

up to 1,100 perfectly sized boxes per hour.

Future-proof your packaging with Sparck Technologies.

The rise of

fit-to-size

What drives the rise of fit-to-size packaging automation? Simply look at today’s most pressing challenges.

Labor

Wages are rising and employees are hard to find. With Sparck, one machine can do the job of twenty manual packers.

Throughput

Boost the speed of your parcel packaging process with up to 1,100 boxes per hour, getting orders out the door quicker than ever.

Freight/DIM

Shipping costs are soaring. Fit-to-size auto-boxing reduces shipping volume and material usage, avoiding hefty DIM charges and saving on freight costs by fitting more boxes per truck.

Sustainability

Sustainability is key for business today. Sparck's technology eliminates excess materials, reducing waste and trucks on the road, shrinking your carbon footprint.

Electrify

efficiency

Discover our commitment to pioneering innovative automated packaging solutions that improve efficiency.

Fit-to-size

from

a-to-z

From rack to truck, how does fit-to-size automated packaging fit in your packaging process?

Fast or

furious?

Explore the CVP Impack and CVP Everest. Dive into a side-by-side comparison to discover which solution fits your packaging needs.

Strength in numbers

50%

in volume savings

30%

in material savings

20

manual packing stations

Your business is our business

Sparck works across a range of sectors, focusing on the industries with the greatest packaging challenges. Check to see how we auto-box your products.